What is a cutting wheel or cut off the wheel?

Vi Plus Cutting wheel or Vi Plus cut-off wheel differs from the grinding wheel in function and structure. The grinding wheel uses an abrasive to grind large pieces of material of a workpiece from a shallow angle, and it generally makes narrow, precise cuts at <0 – 90-degree angles. Accordingly, cut off wheels are often thinner than grinding wheels So they don’t have the side strength needed for side grinding, their minimum consistency makes them better for clean, accurate and sharp cuts.

Vi Plus – Batra Son offers 4 inch cutting wheels for different operations. Batra son gives everything from a 1-millimetre wheel to an extended periphery wheel for larger cuts. This companion to the cut off wheel covers the differences between different cutting wheels

TYPES OF SOME PRIME CUTTING WHEELS

It come in many types. Some main common types are type 1, type 27, type 41, and type 42; among them, the different figures signify the wheel’s shapes and properties.

TYPE 1 OR TYPE 41 CUTTING/CUT OFF WHEEL

Type 1 cutting wheel, also known as a type 41 cut-off wheel is fully flat. It’s generally considered the most effective wheel type for a general each-purpose wheel. Because it lacks a depressed center, it provides a different cutting face and minimizes hindrance with the workpiece.

Article: Best Guide to Understand Self Drilling Screw

The flat profile helps produce deep 90- degree cuts into materials. It allows for the depth <0-90 degree cut at the expenditure of the operator small quantum of visibility. So, their straight profile and the way they mount close to the guard can dwindle visibility for the operator; type 1 wheel is exceptionally useful in grinders, die grinders, high-speed saw, stationary saw, and hash saw.

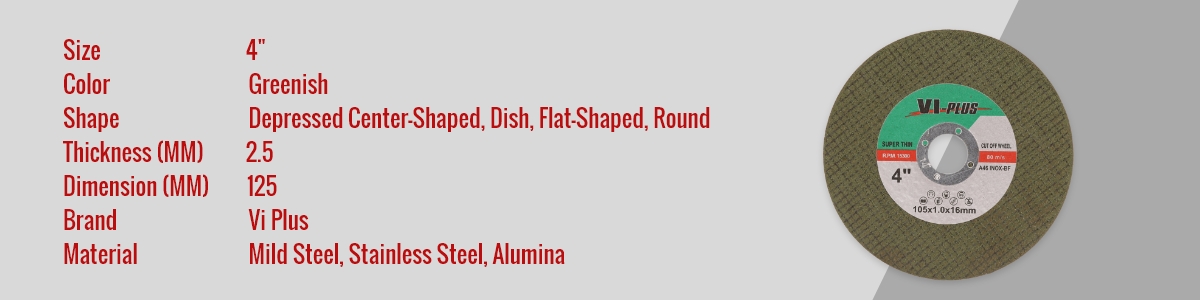

| Size (Inches) | 4″ |

| Color | Greenish |

| Shape | Depressed Center-Shaped, Dish, Flat-Shaped, Round |

| Thickness (Millimetre) | 2.5 |

| Dimension (Millimetre) | 125 |

| Brand | Vi Plus |

| Material | Mild Steel, Stainless Steel, Alumina |

TYPE 27 CUTTING/CUT OFF WHEEL

Rather than being fully flat, a type 27 cut-off wheel, also known as a type 42 the cut-off wheel has a depressed centre. The depressed centre

allows for added concurrence when the operator works at a constrained angle. However, it gives the wheel limited cutting capability when working around corners, biographies, or extrusions. The depressed shape allows a raised hub to hold the wheel securely. The profile of a depressed-centre cut-off the wheel gives the operator a better view of the cut, and it provides the capability to flush- cut because the raised hub means the locking nut can be adjourned.

Vi Plus Cutting wheels generally contain many different parts. First, the grains that do the wheel, the bonds that hold the grains in place, and the fibreglass reinforce the wheel.

The grains within the abrasive of a Batra son cutting wheel are the patches that perform the cutting. Grains may come in several types. Common types grains for the cut off wheel include ceramic alumina, zirconia alumina, aluminum oxide, and silicon carbide.

Zirconia alumina provides a superior cutting for steel, structural steel, iron, and another essence, and it’s ideal for rail cutting and other heavy-duty operations. It represents a fast cut and a long life and holds up under extreme pressure.

Aluminium oxide is a common abrasive grain. It provides a fast original cut-rate and harmonious performance for the steel and other substance.

The grain’s fortitude helps determine its physical and performance parcels as well. The fortitude refers to the size of the individual abrasive patches, in the same way sandpaper grains admit bracket by their size.

Manufacturers frequently relate to the potential grade or hardness. The grade represents not the hardness of the abrasive grains but also the hardness of the bond holding them in place. Communally, under identical conditions, a harder bond means the cut off wheel will have a longer

A softer bond does give certain advantages. It sheds its grains more fleetly to give a briskly cut. The bond holds the grains in place with a stronger bond after being worn.

A softer bond releases them briskly to reveal fresh, sharp grains more frequently and increase the wheels cut-rate. With certain substances, it’s important not to introduce pollutants into the essence when cutting. When cutting new steel and aluminium, always make sure the abrasive contains less than 0.1 of chlorine, iron, and sulphur, thereby emptying its contaminant.

BatraSon

Vi Plus

Leading Industrial Hardware And Tools Wholesaler

OPTING CUTTING WHEEL SIZE

With the tool and the operator have access to will frequently determine the wheel size, and opting for the correct size for the given operation is also essential. Choosing the correct size involves calculating the right rate of revolutions per nanosecond (RPMs) — the RPM standing of the slicing wheel should match or exceed the RPM standing on the grinder that will use it. In addition to vindicating the RPM standing, it’s also important to ensure that the wheel fits on the tool without snooping with or removing the guard.

CUTTING WHEEL CONSISTENCE

The cutting wheel consistency frequently depends on the perfection and delicacy necessary for the cut. A thinner wheel can perform with less delicacy and perfection for a largely precise cut. They cut more snappily and induce lower heat. The thinner wheel also removes less material with each cut, ideal for repairs or fitting up the corridor. The dicker is that they tend not to last as long as a thicker wheel under identical conditions. A thicker wheel may be suitable in operations where perfection and delicacy aren’t as critical.

Vi Plus offers 4-inch ultra-thin high-performance cutting wheels

Batra son – Vi Plus has an instigative new line of chop, stationary, and high-speed saw wheel. The chop saw wheel have a 3/ 32- inch consistency, and the high-speed saw wheel and stationary aphorism wheel have a 1/ 8- inch consistence. These cutting wheels are ideal for cutting operations in fabrication, construction, and rail diligence. Some technical models can give precise rail cutting, purr-free cutting, and super stud cutting for heavy-duty operations.

CUTTING WHEEL APPLICATIONS

Vi Plus cutting wheels offer distinctive shapes for different cutting operations. We have excavated into the common grains used in the cutting wheel and how they’re optimized for use on different essence. We have explored the way periphery and consistence affect wheel speed and perfection. Now let’s look into many operations for artificial and professional cut off wheels and how to choose the right wheel for these uses.

GENERAL FABRICATION

In general essence fabrication, 0.045- inch wheel compasses are common choices. With thinner accoutrements, an operator may choose a 1-millimetre wheel for lesser perfection, lower heat generation, and smaller churrs that will bear junking before welding. The choice of grain will probably depend on the material composition of the workpiece advanced-performing grains for structural steel and delicate-to-cut materials, adulterant-free wheel for new steel.

PIPE CUTTING

In essence, pipe fabrication, the choice of cutting wheel frequently depends on the periphery of the pipe to be cut. For a 3/ 4- inch or lower pipe, 1/2- inch periphery will generally be sufficient. For a pipe of over to 21/2 elevation, a 6- inch cutting wheel is effective, and for a pipe of over to 31/2 elevation, a 9- inch cutting wheel is frequently most suitable. It’s also judicious to choose the thinnest wheel possible to minimize heat and disunion and use a type 1 wheel for a deeper cut unless the operation imposes a particular constraint.

For larger pipe frequently planted on the channel, a depressed-centre cutting wheel provides added concurrence when working at a constrained angle, and 0.045- inch wheel consistency is ideal for cutting operations in fabrication yards or on the right of way for field repairs.

INDUSTRIAL HEAVY WORKS

When an operator is working on a boats or truck confined, hard-to-access spaces, making a cutting wheel last as long as possible is frequently precedence. For this reason, the driver will frequently want to choose a harder, potentially longer-lasting wheel like Tiger Ceramic. Still, when drivers must use air tools whose hoses have stretched over long distances to pierce delicate areas of the boat, the tools may be underpowered.

In this case, a wheel with a soft bond will be ideal because they make it easier to maintain a fast cut. In shipbuilding, the work material frequently influences the cut off wheel selection. An operator may want to elect it that won’t load or go over when working with aluminum.

WELDING MEDICATION

Preparing for welding generally involves exact substance cutting. With an introductory cut-off, perfection isn’t a critical operation. Still, with complex work or repairs that need to save the original aesthetic rates of the material, perfection can save time and plutocrat. Using a 0.045- inch cutting wheel a little further than a millimeter thick is common in welding to allow precise and accurate cuts.

For precise cuts on thin distance substance, biographies, and small periphery rods, a 1-millimetre Vi Plus wheel will give smooth cutting and exceptional control for clean, ultra-precise cuts.

Vi Plus Cutting Wheel

In Railway Works

Ultramodern railroads use hard-to-cut amalgamation brands, so a high-performance cutting wheel is necessary for high-speed gas sayings. A tone-stropping zirconia alumina grain that retains a high cutting performance throughout the life of the wheel offers excellent performance. The Vi Plus 4 – inch cutting wheel is designed specifically for high-speed gas saw and deliver the high-performance results demanded to increase productivity and profitability.

Vi Plus Cut Off Wheel

In Construction Works

Structure and construction spots feature a wide variety of essence cutting operations. Operators frequently look for a vi plus cutting wheel that can do it all, from cutting off rebar to making long cuts on distance essence. Numerous times, an aluminium oxide wheel provides the right blend of versatility, performance, and price. Vi Plus offers flat and depressed-centre cutting wheels in 4 inches for right-angle grinders.

These large-periphery cutting wheels have several hand wheels designed with the construction assiduity in mind. For chop sayings, the line includes a wheel designed for super stud cuttings and options for purr-free cuttings that feature a single subcaste of fibreglass. The high-speed aphorism immolation includes a wheel with three layers of fibreglass for more support in heavy-duty cutting operations.

THE BENEFITS OF SUPERIOR CUTTING.

In your artificial and professional operations, make Vi Plus Abrasives your trusted source for face exertion results. Vi Plus Batra Son Cutting Wheel comes in best type, grains, bonds, compasses, density, technical features, and price points, so we can help you find the wheel or small cutting discs right for your operations.

The value you will admit extends far beyond the purchase of a cut off wheel. Our Value Package offers new advantages similar to safety training to grease your cut off wheel’s safe and effective use and direct field support to answer your questions and help you make your installation more effective and productive.

Vi Plus Cutting Wheel 4 Inch best price – WhatsApp or Call us (+91-9999933445).

About the Company

Established in 1981, New Delhi, we, Batra Son, are among the leading Manufacturers, Wholesalers and Suppliers of premium quality Industrial Fasteners. These are manufactured at our modern infrastructure facility using raw materials and components that are tested and certified on their quality. The range of products that we offer is vast and offers multiple choices to the clients so that they can easily take their pick.

Our products are easily accessible to clients within the stipulated period of time. Our products are stringently tested on their quality by a team of highly experienced and well-qualified professionals. The products offered by us boast of unmatched quality, durability and damage-resistance. These are available to clients in user-friendly specifications

| Nature of Business | Exporter and Manufacturer |

| Additional Business |

Wholesaler Supplier |

| Company CEO | Ravi Batra |

| Total Number of Employees | Upto 10 People |

| GST No. | 07AAGPB5915R1ZD |

| Legal Status of Firm | Individual – Proprietor |